FACTORY-READY TECH PACKS & DXF PATTERN FOR APPAREL BRANDS

Technical design support that helps you move from concept to production clearly, accurately, and without costly delays.

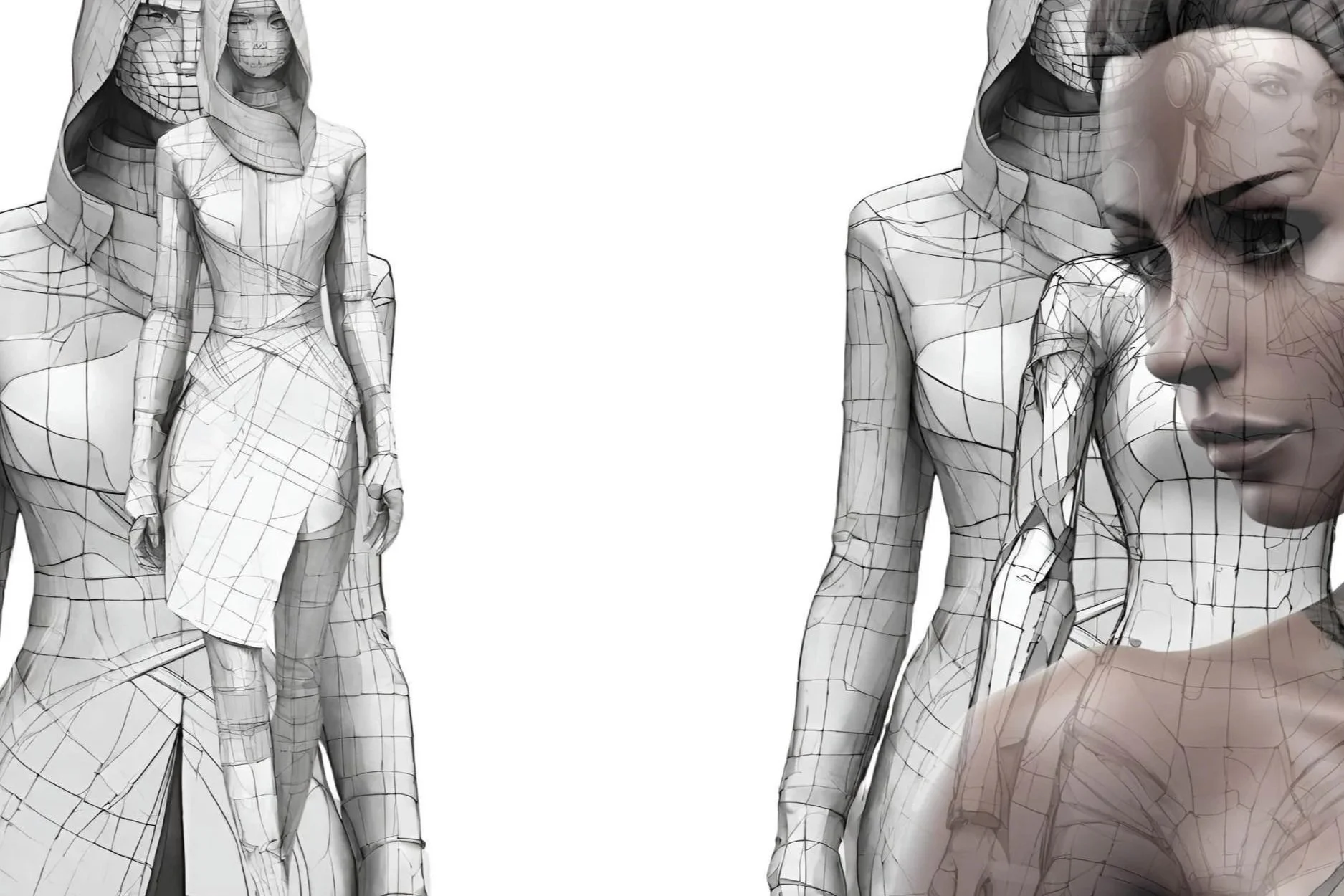

DIGITAL PATTERN MAKING

3D TECH DESIGN SERVICES FOR FASHION

FIT AND SIZING STANDARDS

START CLOTHING PRODUCTION FASTER

TECHNICAL DESIGN SERVICES FOR

Apparel brand, startup, or manufacturer who:

Is preparing styles for sampling or bulk production.

Needs clear, professional, and factory usable tech packs.

Wants DXF pattern and production files done right the first time.

If production mistakes are expensive for you, this service is built for you.

WHAT WE DO

Production-ready technical design services for the apparel industry, including:

Specs & construction detail (apparel).

Comprehensive, factory-ready tech pacs.

DXF pattern development, grading, and sizing.

Production guidance and ongoing technical design support.

All documentation is created with real factory requirements in mind—not just visuals.

WHY WORK WITH US

Factory-focused approach—Files formatted and detailed for real production environments.

Clear communication—Reduces sampling errors, revisions, and delays.

End-to-end support—From tech packs to patterns, to sizing, to production handoff

Scalable solutions—Support for a few styles or full collections.

We work as technical partners, not just a service provider.