How to Create Tech Pack for Clothing Development and Manufacturing

TAAS INC. by Nina Nikolic

January 29, 2019

Tech Packs for Fashion

For many years, I was a fashion technical and production “go-to person.” Tech packs were part of my daily joys and sorrows. Each day had its unique drama moment related to technical or production problems. In most cases, we found the problem within the tech pack. Sometimes, important construction details or specs got ignored, causing a major upset.

Days were dull (read superb) if everything went well. Other times, days would turn into Dante‘s Inferno (all nine circles), devouring our time and energy.

Throughout my technical journey in the fashion industry, I encountered many techpack variations created on various platforms.

PLM (product lifecycle management), PDM (product data management), Excel, and Adobe Illustrator are the most popular tools for tech pack creation.

What is a Tech Pack?

A tech pack or technical package is a critical document with detailed information about the garment you plan to sample and manufacture for commercial sale. Having a tech pack or technical package is important when creating a garment.

This document contains detailed information about the garment the factory will use to develop and produce the style. It's important to note that each clothing style must have its technical package, even if it appears similar with just minor differences. This ensures that the factory can accurately create the garment to your specifications. A detailed tech pack for each style will secure successful communication with your factory and a smoother production process.

How to make a Technical package in Excel? Best Practices and Tips

Step 1

Create an Excel document and name it with a unique style number and description (e.g., 1001 V-neck tee). You will most likely communicate all garment changes and updates to your vendors via style numbers rather than style descriptions.

Tip: Create a style number coding list and issue styles from the list. You might want to define coding by clothing category specific to your brand (e.g.,1000-tops, 2000-bottoms, 3000-dresses, etc.)

Step 2

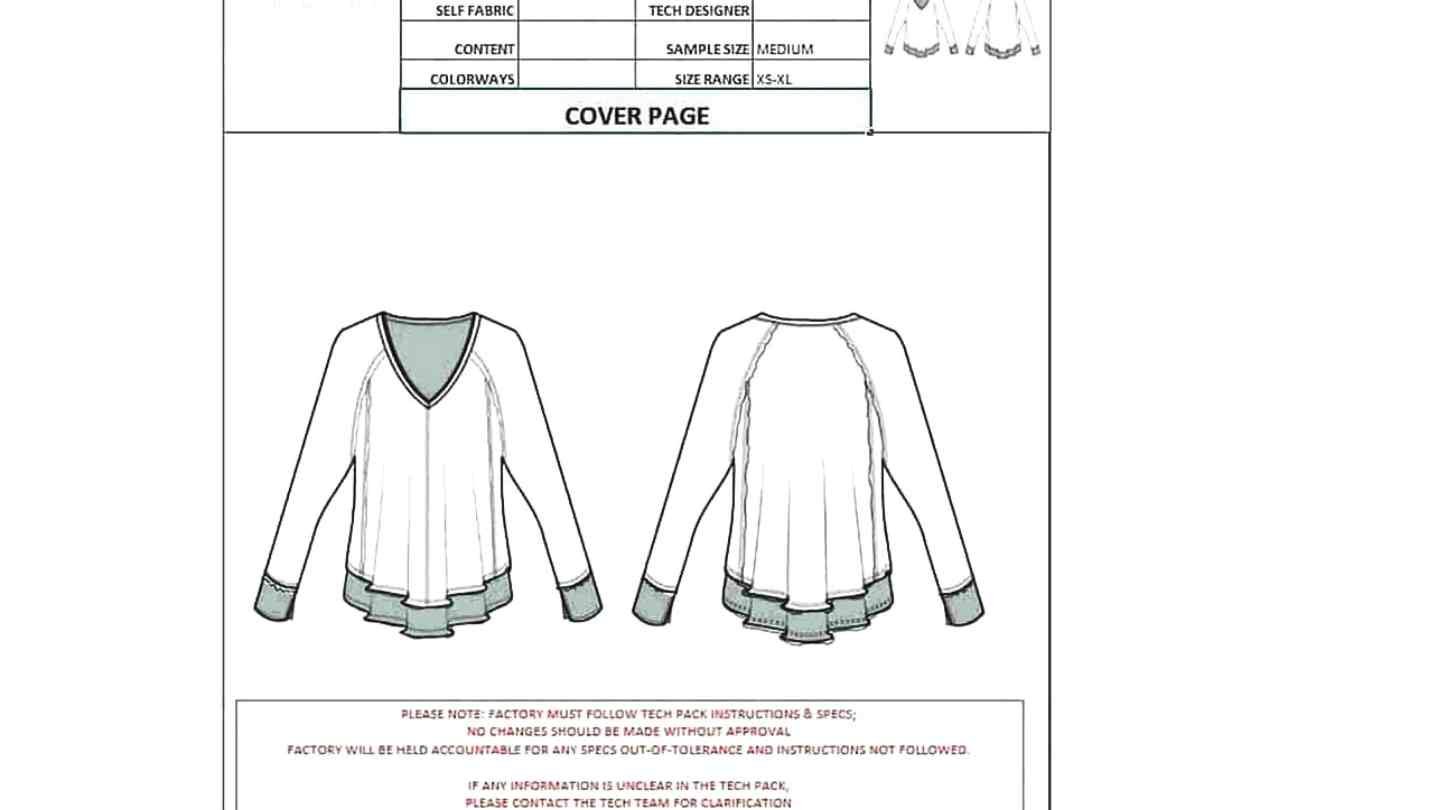

Create and format the first page (the cover page) to include the necessary information:

Style number and style/garment description

Factory name

Fabric information

Fabric content

Colorways

Base Size (sample size)

Date

Company’s name/Logo

Front and Back sketch

You can format the page to your liking. The example shown below is guidance, not a rule.

Step 3

Copy and paste the page and name the new tab (e.g., Construction Page, Artwork page, etc.). Repeat this step to create as many pages as needed.

The Tech Pack Structure

Tech Pack has a few pages or tabs. Each page contains information related to the particular garment segment. Providing clear and comprehensive information in the tech pack will ensure the expected outcome throughout the sampling and bulk production process.

Consider that most garments are being produced overseas. Technicians will translate tech packs to the best ability. Often, translation or interpretation of the crucial construction detail will be erroneous. Consequences are dire and might lead to a faulty final product shipment; therefore, heavy financial losses.

To prevent such a mistake, include many visual descriptions of the garment in the tech pack. Sketches and photos will provide better quality information than writing a “novel” when describing desired design details for the clothing.

However, many drawings and photos will increase the file size. Storing and e-mailing large files might become a major headache. There are many available platforms to store and send large files. It is worth spending some time researching the most suitable one for your needs.

A typical tech pack will include:

Cover Page

Designated for flat sketch placement (front and back). Fashion designers use floats, while technical designers prefer flats.

The Flat sketch is a line sketch created in Adobe Illustrator or by hand. The illustration is more technical and describes garment engineering and construction with stitching and shaping devices.

A float sketch is a simplified fashion drawing of the garment showing the drape, color, and texture. Some fashion designers prefer to make sketches by hand; others use Adobe Illustrator. Floats with color and texture are more attractive than flats. Brands like to use color floats for presentation purposes.

Inspiration Page

Includes a photo of the actual garment for fit and styling reference. Sending the sew-by-sample to the factory to follow for construction and fit is the way to go.

Construction Page

Includes descriptions of construction methods. Seam finishes (stitching), pocket placement position and dimensions, and other specific styling details are essential garment information that the sample maker or factory needs to know.

If the garment construction is more complex, you might include additional pages to illustrate specific stitch details such as reinforcement stitch (bartack), topstitching, or decorative stitching.

Seam finish abbreviations are very common when describing construction details. The majority of domestic and overseas factories are familiar with acronyms for seam finishes. Let’s name a few.

SNTS-single needle topstitch

DNTS-double-needle topstitch

SNES-single needle edge stitch

CS-cover stitch

Abbreviations with definitions vary among different companies. For a clear understanding of construction methods, each company should compile a vendor manual or list a clear description of each acronym in the tech pack.

Bill of Materials or BOM page

This page contains a list of all components needed for garment making. The list should have detailed information for each element, as the accuracy of the data will play an essential role in garment pricing. BOM page details are:

Fabric information-includes width, weight, color, and content. Specifying the fabric (woven or knit) and type of finish (pre-shrunk, washed, enzyme wash) is important. Include the lining and interlining information if applicable.

Trim information-includes type of buttons, size, and quantity, zippers, elastic, cords, etc. List the color and article number. Button and zipper tape color is often listed with the acronym DTM (dye to match). It means that the button color must match the garment color.

Thread-it is important that thread weight and quality match the fabric weight. The allocated factory usually knows this, but listing the thread weight and color does not hurt.

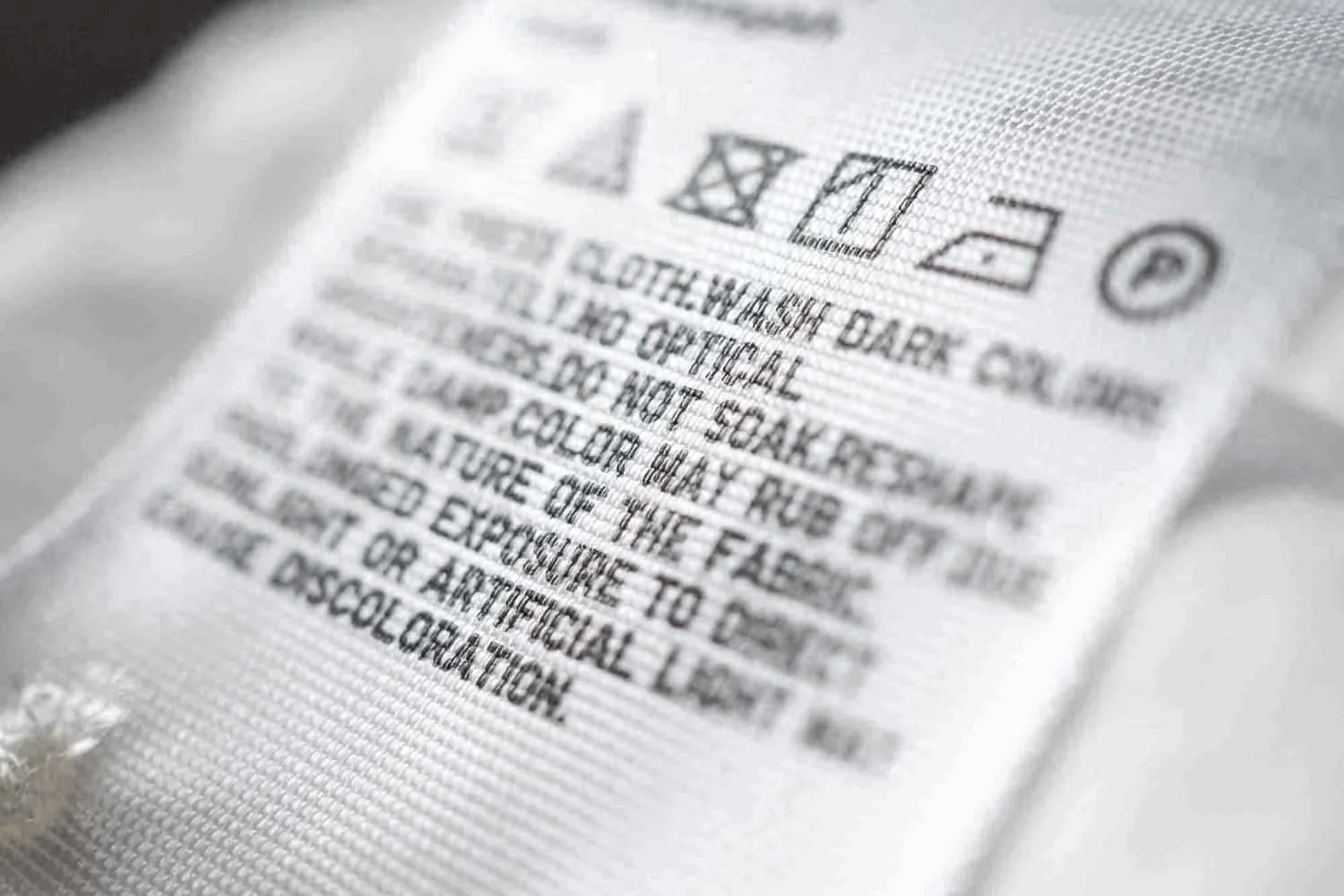

Label and Hangtag-Include a simple sketch illustrating the placement and dimensions of the main label, size label, and COO (country of origin).

Example of Label and size placement description:

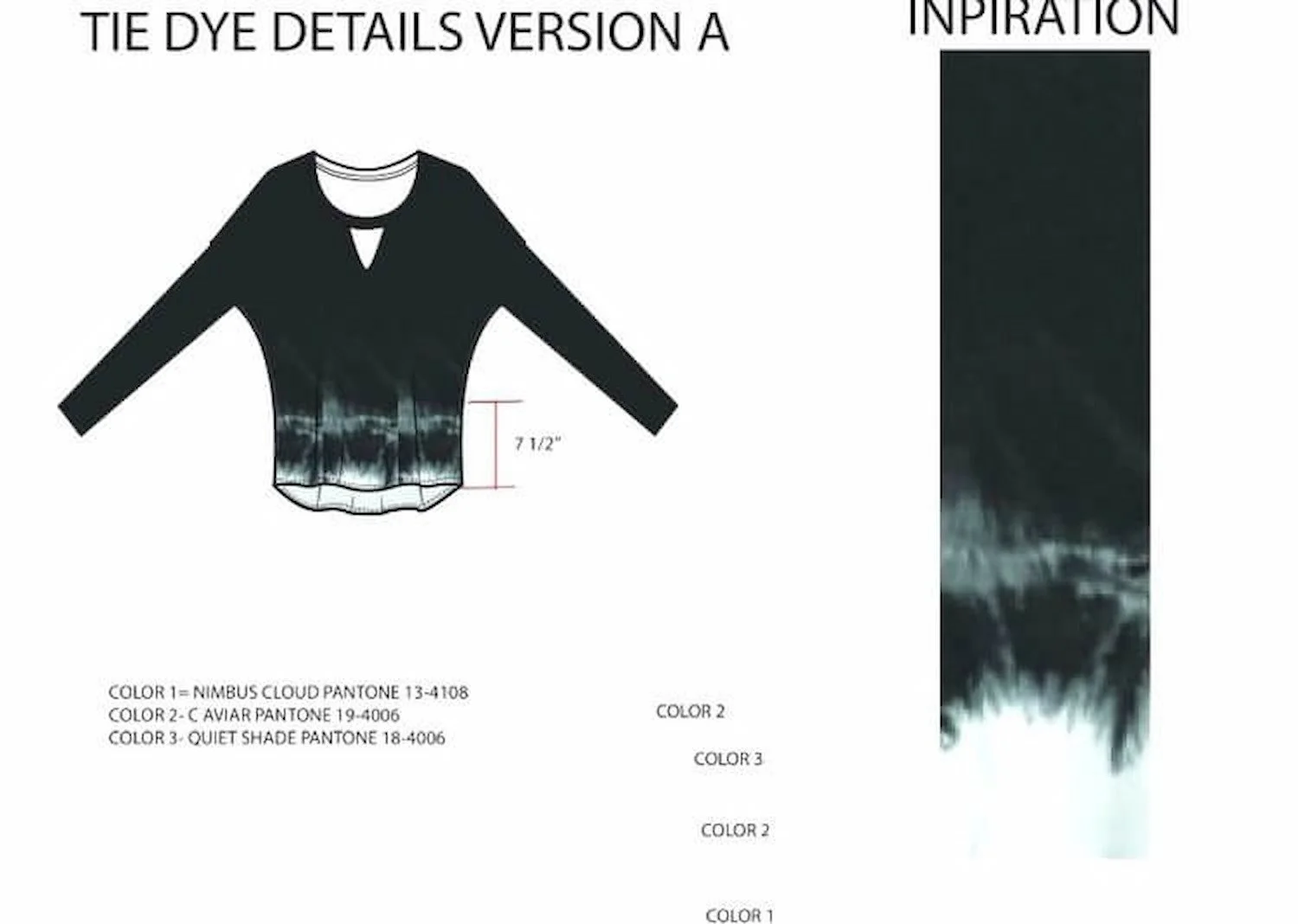

Colorways page

Specify each color by the name and Pantone number (preferred method) or CMYK/RGB if created in Adobe Illustrator or Photoshop (if no other information is available) for all colorways for the style. For printed fabrics, make sure to include a repeat snapshot and list all colors with Pantone numbers used within the print.

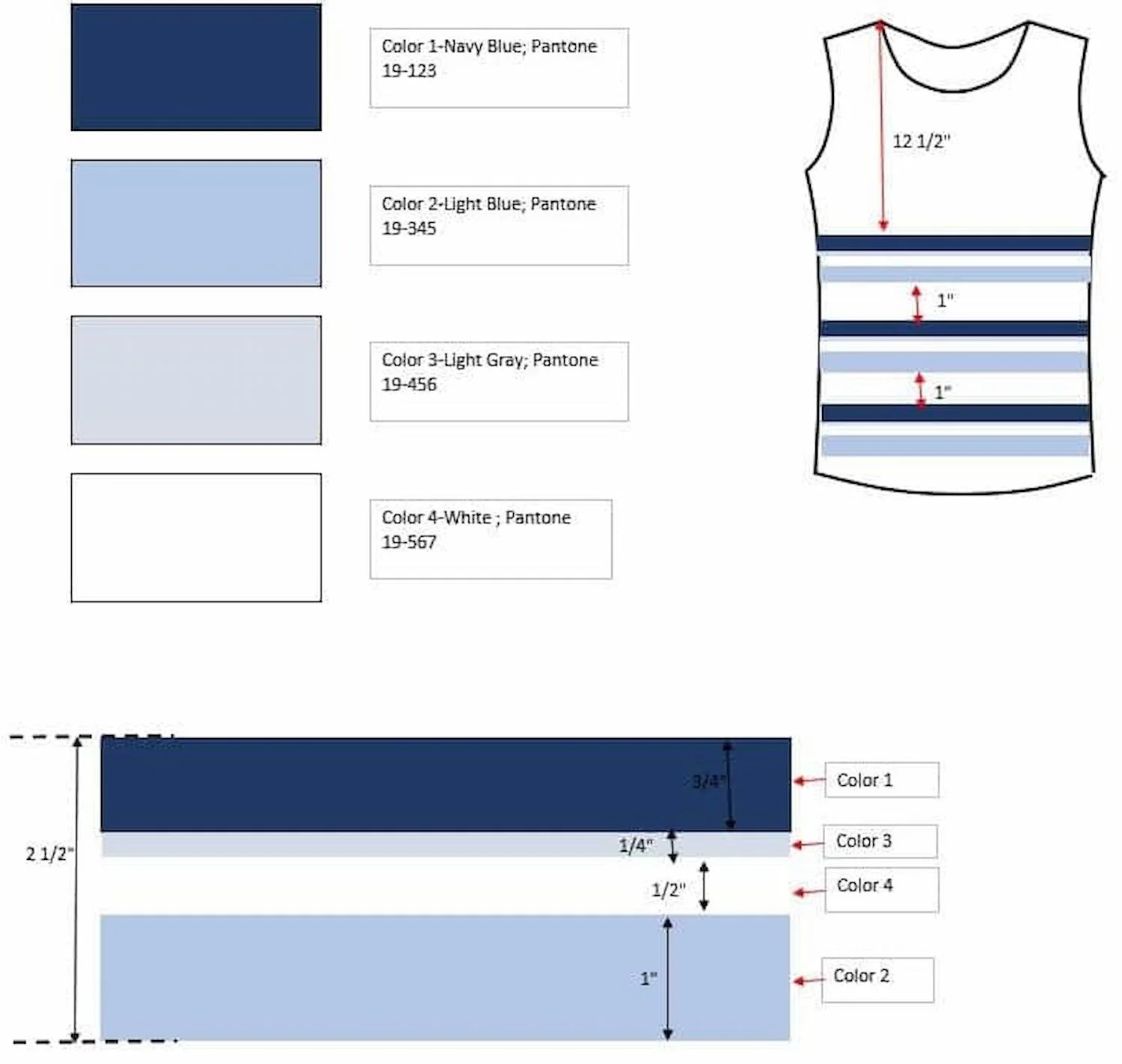

Artwork page

Include information about the logo, embroidery, or other decorative, top applied details. This page should have exact dimensions and specific placement diagrams on the garment. Include detail drawings with placement dimensions (logo, embroidery, or stripe details).

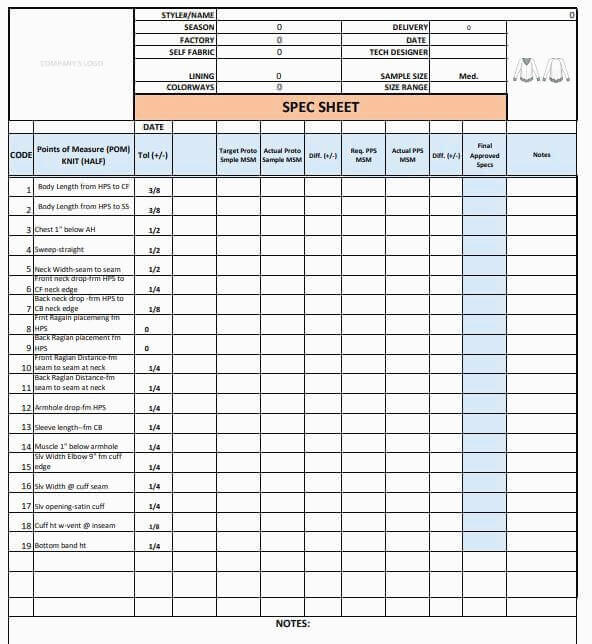

Spec Page

What is a spec?

Spec or garment specifications are the most critical part of the tech pack. Specs are the measurements of the finished garment. Each measurement is called a Point of Measure or POM. The description of each POM should be specific to assure measurement method consistency. Most companies create their own “How To Measure” manual with the code number for each POM.

The spec sheet, points of measure, and recorded specs should be well-organized documents as they will become a reliable reference for the best garment fit.

The sampling process focuses only on one size. After a fit approval of the physical sample, the graded spec is submitted to the factory for the final bulk production. Graded spec refers to the size range that the factory will make and ship. The spec sheet contains the garment spec history throughout the development cycle.

Tip: specs for knits are recorded in half measurement, and specs for woven garments are commonly referred to as full measurement (full circumference).

Full-Size Spec Page

This page includes approved PP (pre-production) specs with grade rules for each size. It is critical information for the factory to produce a size run or size range. The clothing sizes are commonly created as Alpha (XS to XL) or Numerical (e.a. 2-10). Sizing and size range varies among brands on the market, and you should get familiar with sizing methods and grade rules to refine your brand’s sizing and fit signature.

Comments Pages-Fit History

Comment Pages or Evaluation comments present a visual record of physical samples fitted on the live model. The best practice is to create a comment page for each fit sample (e.g., Development Comments, PP Sample-Pre-Production Comments), take photos (Front, Side, and Back), and include workmanship, fit, and spec comments. This is the best way to communicate any changes you want to make to the style. Word choices and sentence structures should be simple. Whenever possible, describe the style with visuals. This approach will bypass the language barrier easier.

To conclude, the technical package is the most important document you need to engineer while planning to sample and manufacture the clothing line.

Contact us for more information about the tech pack and digital product development process for the clothing line creation.

Learn more about fashion technology and sustainable practices within the apparel industry.